Cell culture systems

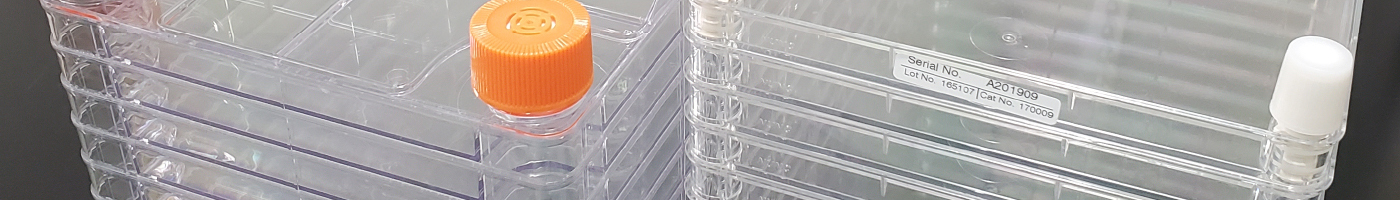

A growing number of facilities are using multilayer vessels in the production of cellular medicines and vaccines. Multi-layered vessel culture is labour-intensive due to the repetitive handling of heavy vessels and tasks such as cell observation and the pumping, draining and transporting of culture fluid. Our cell culture systems enable labor saving and improve quality control through automation. Different models are available depending on certification requirements, applications and quantities.

- Compatible vessels

- Thermo Fisher Scientific: Cell Factory

- Corning: Cellstack, Hyperstack

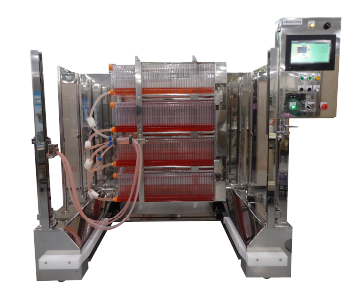

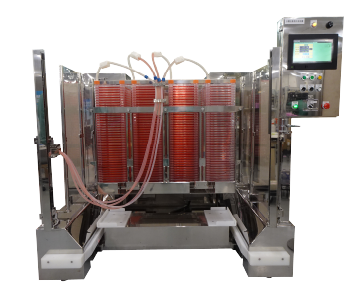

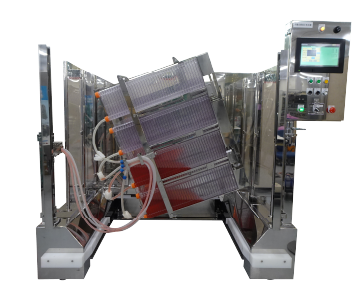

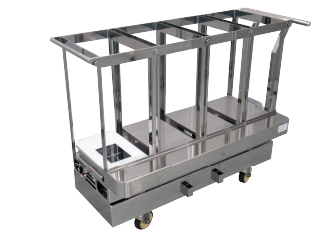

Automatic Manipulator

- Features

- Automates the processes of seeding, media exchange, cell peeling and harvesting

- Multiple multilayer vessels can be handled at the same time

- Cleanliness class B compatible

- Machine operation tailored to your needs

- Pumped fluid

- Peeling

- Harvesting

- Harvesting

- Manipulation video

(Left and Right)

- Manipulation video

(Front and Rear)

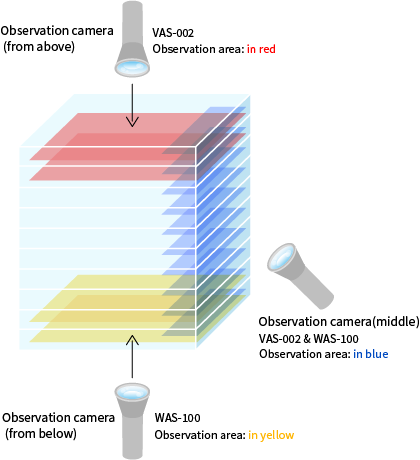

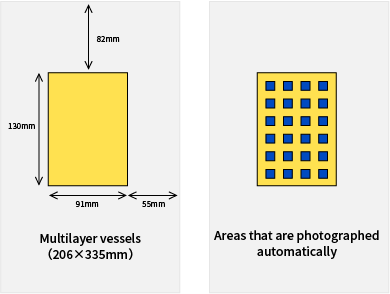

Microscopic Observation System

- Features

- Observe each stage of the multilayer vessels

- Observation from above (VAS-002)

- Observation from below (WAS-100)

- Tailored to your requirements

Incubators

WAKEN B TECH incubators and TAITEC incubators are compatible with our multilayer vessel transfer carts.

WakenBtech: https://www.wakenbtech.co.jp/product/post-7653

TAITEC: https://taitec.net/

Pumping Unit

- Features

- Can be used in conjunction with our Automatic Manipulator to automate the processes of injecting / dispensing cell culture fluid into and from multilayered vessels.

- Cell culture fluid can be pumped into and drained from multiple multilayer vessels; the liquid flow rate and path can be controlled.

Incubation Monitoring Systems

- Features

- Cell status can be observed while the cells are still in the incubator

- The photographs can be used to measure cell count and density

- Use time-lapse to take photos automatically

- Wireless connection (Wi-Fi) between the scanner and PC eliminates the need for cables

Vial Feeder Unit

- Features

- Vials can be removed from their dedicated resin container for automatic replenishment

- Container stacking and unstacking mechanisms allow dedicated containers to be stacked 5 high for processing and returned 5 high after vials have been filled

- Capable of processing more than 400 vials per minute

- Tailored to the containers and vials you use

Vial Accumulation Unit

- Features

- Vials are set in a special aluminum case for automatic accumulation

- The aluminum cases are stored in a dedicated five tier storage rack and transferred to a conveyor

- Able to process more than 400 vials per minute

- Tailored to the containers and vials you use